I. General Situation

The operating rooms and auxiliary rooms in the outpatient department of a hospital are equipped with a purification air conditioning system, of which three operating rooms are of class III, the purification level is 10000, and the purification level of auxiliary rooms (including clean channels) is 100000.

II. Construction arrangement

1. Before the decoration construction of the operation area, a detailed construction plan shall be prepared and submitted to the supervising engineer for approval. 2. The construction of construction decoration in the operation area shall be carried out after the completion of the upper roof waterproof, outer door and outer window installation, and the completion of the rough decoration of the same floor, including the indoor decoration, door and window installation and gap sealing, as well as the sealing operation of the joints between the installation of various pipelines, lighting fixtures, purification air conditioning equipment, process equipment and the building.

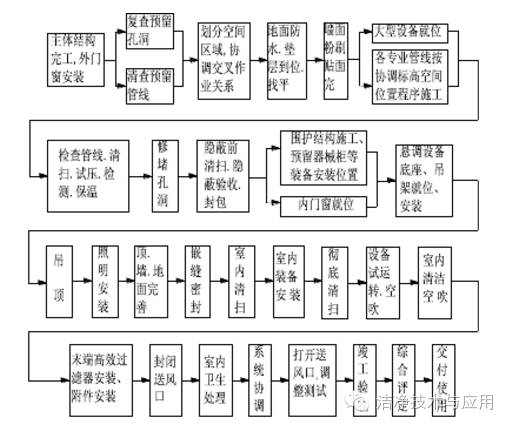

3. Strict construction procedures must be established between the construction decoration engineering and each professional work type. The clean room construction procedures are shown in the following figure. The construction schedule of the construction decoration shall be clearly formulated with the construction cooperation plan of other professional work types. The construction shall be carried out in accordance with the procedures and cooperate with each other.

4. During the decoration construction, the water and electricity disciplines are interpenetrated to install pipelines, boxes, cabinets and appliances, and the ventilation is empty

The air duct, support fabrication and support installation shall be carried out by the dispatching discipline, and the clean air conditioning system installation shall be carried out after the completion of civil decoration.

5. The walls and ceilings in the ceiling of the operating room, as well as the walls of the auxiliary rooms and walkways, shall be painted, and the paint that is flame-retardant, non powdered and cracking, scrub resistant, smooth and non absorbent shall be selected.

6. Before the wall tiles of the operating room are pasted, they shall be strictly selected, warped and irregular tiles shall be removed, and the flatness and gap width of the wall shall be strictly controlled during the pasting, and the brick joints shall be pointed with special glue to form a whole with the tile surface without ash accumulation.

III. construction technical measures and requirements

First, organize engineering technicians to be familiar with the drawings, fully understand the design intent, carry out technical disclosure, and implement in a planned and planned way.

1. General principles of construction

(1) the building decoration shall follow the general principles of no dust generation, no dust accumulation, corrosion resistance, moisture-proof and mildew proof, easy cleaning and meeting the fire protection requirements.

(2) the ambient temperature at the construction site of construction decoration in the operation area shall not be lower than 10 ℃.

2. The procurement and use of materials shall be products that meet the design quality standards and environmental protection requirements. It is strictly prohibited to use materials and coatings with sustainable volatile organic chemicals.

3. Decoration construction of operation area

(1) plastering of wall and ceiling in operation area

① the wall and ceiling plastering above the ceiling of auxiliary room and operating room shall be controlled by high-level plastering standard and fully maintained.

② the skirting should be slightly indented into the wall for 2-3mm. The operating room skirting and the ground cement should be integrated. The internal corner of the skirting and the ground should be rounded with R ≥ 40mm.

③ the corner of the wall and the external corner of the vertical side of the door shall be rounded. Anti collision plate shall be set on both sides of the passage and on the wall at the corner.

(2) ceiling decoration works

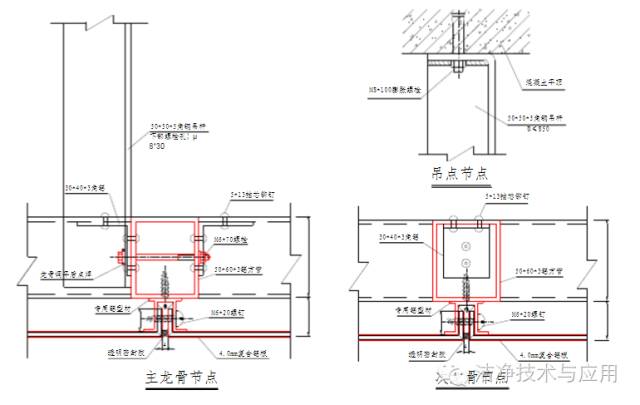

① the ceiling of the operation area adopts the aluminum alloy square tube keel made by the professional manufacturer, the aluminum-plastic plate surface layer, and the panel is pointed with transparent silicic acid to ensure that the gap does not leak air. Because the ceiling is often overhauled by people, its ceiling is firmly connected to the main structure with angle steel of ∠ 50 × 50 × 5 (see the figure below), which should not be connected with equipment support and pipeline support, and there is no upper manhole on the ceiling of the operating room, which can be set on the corridor. Before construction, the plane design shall be done, and the air vent, air return outlet and lamps of air conditioner shall be reasonably planned to meet the functional requirements and make them beautiful.

② the exposed part of embedded iron parts and hanger bracket shall be treated with rust prevention.

(3) anti static coil floor in operating room

① material requirements: the operating room floor must meet the requirements of anti-static performance, with tensile strength of 25-35mpa, volume resistance, surface resistance of 104 Ω - 107 Ω, half-life of less than 1s, abrasion, sag and other indicators in line with the requirements of relevant standards, using matching adhesives and ground electrode.

② construction process: base inspection and cleaning → grid snapping → glue brushing → paving → slotting → welding seam → cleaning and waxing → acceptance.

③ quality control requirements

A. the surface of base course shall be clean, dry and flat.

B. avoid less than 1 / 2 board width and narrow strip during grid snapping.

C. when applying glue to pave and paste the floor, the appropriate temperature is 15-35 ℃, and the relative humidity is less than 70%. Use the rubber to make it compact by loose beating. The skirting part is turned over from the ground to the lower opening of the wall tile. After survival, it is slightly indented in the wall. It is forbidden to go on the person within 24 hours after paving.

D. after laying for 48h, use a slotting machine to slot at the joint, and use special welding rod after cleaning

For welding, the weld strength shall not be less than the floor strength, and the weld protruding from the floor shall be planed.

E. the floor surface shall be flat, smooth, firmly pasted and free of blisters.

F. after the floor construction is completed, the floor volume resistance and surface resistance must be tested. ④ finished product protection

During the subsequent process construction, the floor surface shall be covered with clean cloth to prevent damage and pollution.

(4) auxiliary floor tile surface course: according to the design requirements and relevant standards, the material shall be selected, and the paste shall not be empty, the flatness and height difference shall be less than 1mm, and the brick joint shall be pointed with special pointing glue, so as to be flat and firmly bonded with the floor tile.

(4) doors and windows

① the clean operating room door should adopt the electric suspension type automatic sliding door with automatic delay closing device, which is designed as a spring door, and should be made of aluminum alloy to meet the requirements of sealing and easy cleaning.

② the external windows of operating room and clean auxiliary room must be double-layer airtight windows.

③ the gap between the outer window frame and the wall shall be closed indoors, that is, the positive pressure surface shall be sealed with silicone glue. The gap between the transfer window frame and the wall shall be sealed with silicone glue on both sides of the wall. The door leaves on both sides of the transfer window shall be equipped with interlocking devices.

④ elastic sealing strip shall be continuously laid around the gap between the door frame and the door leaf to form a closed sealing line after the door is closed.

(5) power and lighting works

① closely cooperate with civil engineering to do reservation work.

② the cutting of wire pipe adopts toothless saw to overcome the burr of pipe orifice. Pipe mouth shall be provided with protective mouth.

③ the laid wires are convenient for inspection and replacement. When threading, the sundries in the pipe shall be removed. Except for the connection with the equipment, no joint shall be left in the pipe.

④ before cable laying, the design must be checked and the insulation resistance shall be measured with a 500V megger. The cable can only be set out after it is qualified, and the signboard with cable number, specification and model shall be hung one by one.

⑤ the distribution board shall be dust-proof, the cabinet shall be sanitary before installation, and the door shall be closed tightly after installation. The installation of sockets, socket boxes and wire boxes must be cleaned, close to the wall and installed properly. Ceiling mounted luminaires shall be close to the ceiling and wiped clean. Sealing measures shall be taken for all inlet and outlet pipe heads.

⑥ the sockets, switches, equipment cabinets, etc. that must be set in the clean operating room and the clean auxiliary room are embedded in the wall and flush with the wall.

⑦ there shall be no exposed pipelines in the operating room and auxiliary room. Pipeline concealed works shall be carried out after pipeline construction and pressure test acceptance. The hole around the pipe passing through the wall and ceiling shall be filled with sealing materials and repaired flush

Tight and clean. The air tight gasket shall be pasted around the access of concealed works.

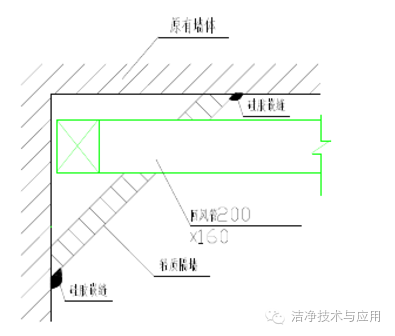

⑧ 回风管及回风口处理:图纸设计为侧墙面回风,为了保证墙面平整,不增加凹凸面,将回风立管移至手术室的两斜对角处,用有一定强度和刚度的表面光洁的轻质板材做成八字形风道,隔墙高2.9m,将回风滤管、过滤器安装在风道内,百叶回风口采用定型产品300×300,风口中心标高为0.35m,叶片竖装,以避免百叶片上积尘,见下图:

4. Construction inspection

During the construction process, the intermediate inspection and acceptance shall be carried out after the completion of each process, and the records shall be kept. After the completion of the clean area, the acceptance shall be carried out in accordance with the building installation acceptance standards and relevant professional standards.

IV. quality assurance measures

1. Strictly implement technical disclosure, technical review, self inspection, mutual inspection, special inspection, raw material inspection, concealed works acceptance and other technical management systems.

2. The professional engineer shall participate in the whole process of construction and implement in strict accordance with the requirements of quality objectives. 3. Select experienced senior Chinese decoration technicians for clean room construction. 4. Strengthen coordination among water, electricity, ventilation and other disciplines.

5. During the construction, the site cleaning work shall be carried out at any time, and the cleaning records shall be made for the concealed space (such as the interior of the ceiling).

6. During the construction process in the operation area, irrelevant personnel shall be controlled to enter the operation site.

7. Protect the finished surface of decoration works to avoid pollution and damage caused by subsequent process construction.

Clean operating room project is a professional, comprehensive and difficult project, with complex design and construction and high technical risk. Therefore, it puts forward high professional and technical requirements for purification engineering company, which requires purification engineering company to have high technical adaptability and flexibility. The purification engineering company is required to have an engineering team with rich experience in design, manufacturing, installation, comprehensive commissioning and after-sales maintenance to strictly guarantee the quality of purification engineering. For more knowledge of medical purification industry, please pay attention to WeChat public address: Aide-188 (Ed purify oxygen supply).