Welcome to ED Medical Equipment Engineering Co., Ltd.

- About Us

-

- Company Profile

-

- Honor

-

- Growing experience

-

- The enterprise culture

-

- Equity structure

-

- Join Aide

-

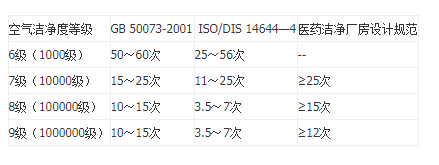

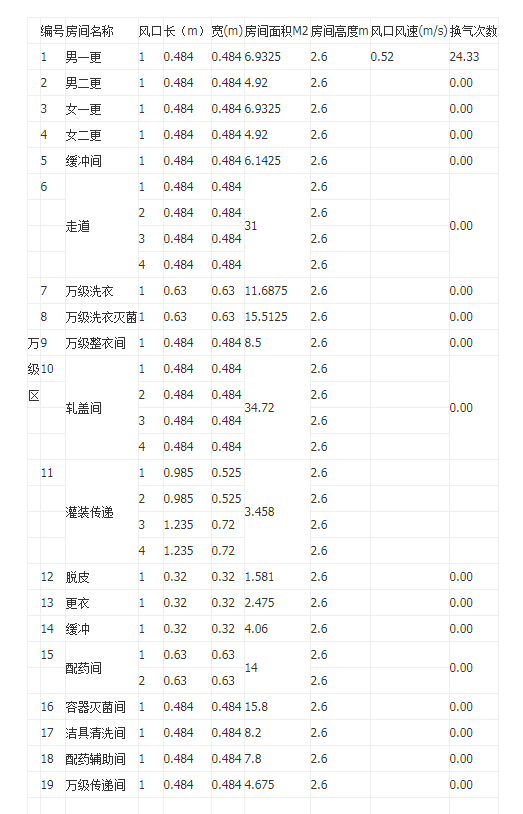

- The wind calculation show

-

- Service support

-

- Sales network

-

- Organizational structure

- News

-

- Company news

-

- Industry Information

-

- conceptual design

-

- Equipment maintenance

-

- technical service

-

- Data Download

-

- Cleaning principle

-

- Common problem

-

- Purification classification

-

- construction technology

-

- Purification drawings

-

- Supply information

- Products

-

- Purification engineering installation

-

- Purification equipment

-

- hepa box

-

- Supporting products of ED

-

- Laboratory support

-

- Medical Writing Table

-

- Control panel

-

- Stainless steel instrument cabinet

-

- Operating Room Air Source Box

-

- Medical viewing lamp

-

- return air grille

-

- Operating room socket box

-

- Medical Hand Washing Pool

-

- Transfer window

-

- Air shower

-

- Air filter

-

- Laminar air supply smallpox

-

- Clean lamp

-

-

- Medical Purification Door

-

-

- Suspension bridge crane series

-

- Bed and Ward Care Series

-

- Clean room air conditioning system

-

- Surgery table series

-

- Shadowless Lamp Series

- Cases

-

- Workshop purification engineering

-

- Hospital decontamination

-

- Laboratory decontamination

-

- National cleaning customer case

-

- Mobile Operating Vehicle Purification Project

-

- Air purification project

- Human Resources

-

- Human Resources

-

- Recruitment information

- Contact Us

-

- Contact Us

-

- Message

PC Edition Touch Edition Statistics Manager