In a clean room, there is little change in the cross-section of the air flow from the air supply outlet to the air return outlet. With the pressure sharing effect of the inlet static pressure box and the high efficiency filter, the flow velocity in the cross-section of the whole room is relatively uniform, but at least in the working area, the streamlines are unidirectionally parallel and there is no eddy current. This is the three characteristics of one-way flow clean room. The streamline here is one-way parallel, which means that the time-averaged streamlines are parallel to each other and have a single direction.

The flow pattern of one-way flow clean room is turbulent from Reynolds number, so the so-called laminar flow in laminar flow clean room and laminar flow in fluid mechanics are completely different concepts. Therefore, the term laminar flow clean room is inappropriate. Some foreign standards and articles also point out this point. For example, the British standard BS-5295 once defined the so-called laminar flow clean room as a one-way flow clean room, but the care habit is indicated as laminar flow in brackets. The former Federal German standard VDl-2083 used the term "turbulent displacement flow" and pointed out in the note that the concept of laminar flow was only used to distinguish turbulent (turbulent) flow clean rooms from turbulent (turbulent) flow clean rooms which appeared earlier than laminar flow clean rooms. The exact meaning of "laminar flow system" was not stratified flow, but turbulent flow. The concept of displacement flow referred to in this chapter is the gradual flow of turbulence. In hydrodynamics, this flow state can also be called parallel flow or unidirectional flow. In 1977, China adopted the term "parallel flow" in the Technical Measures for Air Cleaning, after which it also pointed out that it was customarily called "laminar flow".

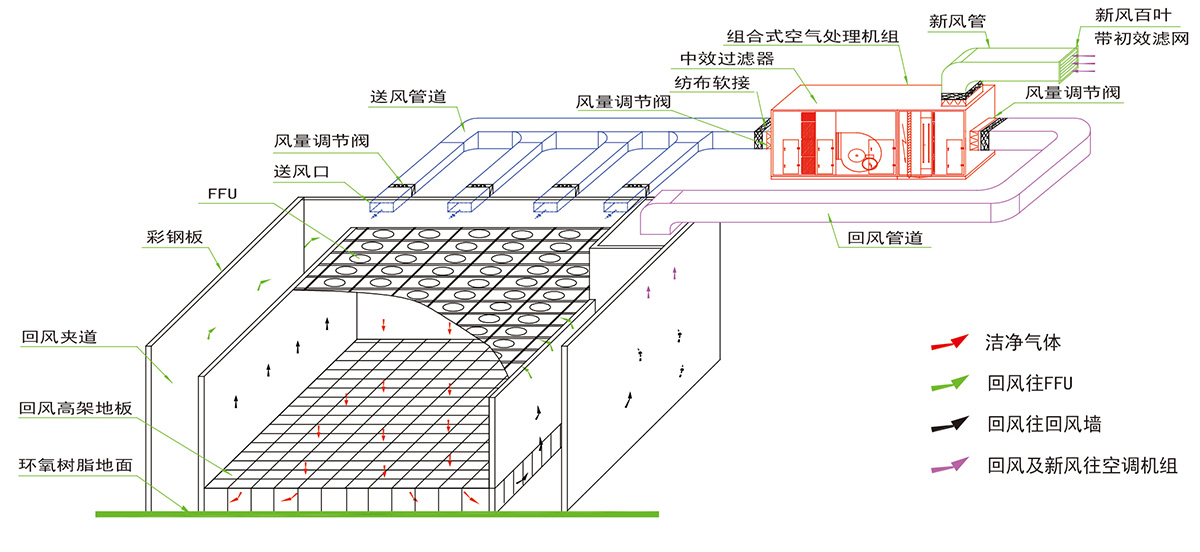

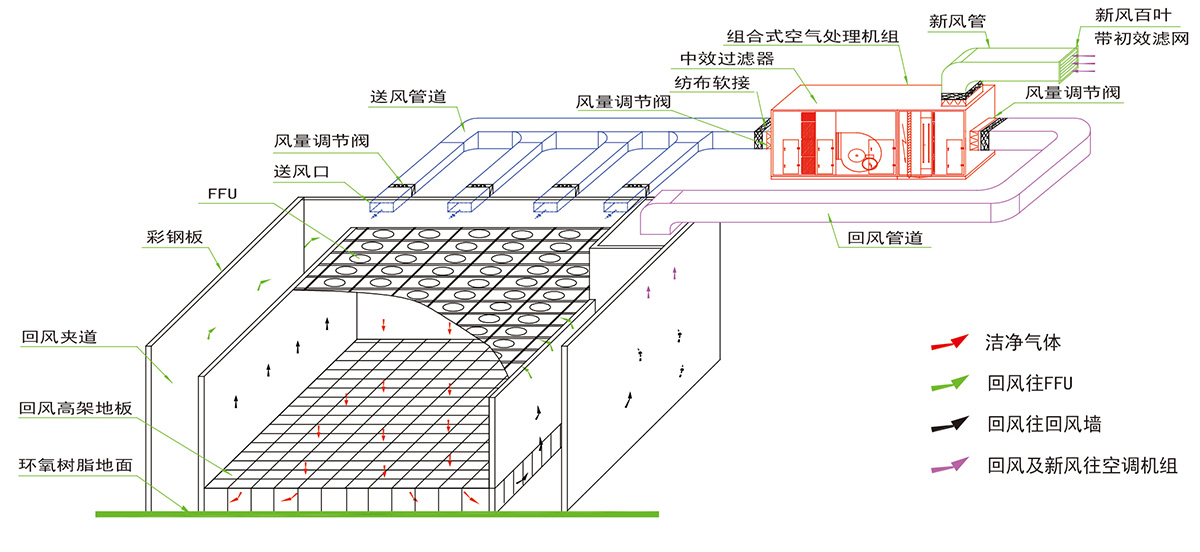

In one-way flow clean room, clean air flow is not one or several strands, but full of the whole room section, so this clean room does not rely on the mixing and diluting effect of clean air flow on indoor dirty air, but on the pushing effect of clean air flow to discharge indoor dirty air along the whole section to the outdoor, so as to achieve the purpose of purifying indoor air. Therefore, some people in the former Federal Republic of Germany called the air flow in the one-way flow clean room as "piston flow" and "advection flow", which the former Soviet Union called "squeezed weak air jet". Clean air is like an air piston, pushing forward (down) along the "cylinder" of the room, so that dust particles can only enter forward (down) without returning, squeezing the original air with high dust concentration out of the room.

In the one-way flow clean room and one-way flow purification equipment, the reverse air flow along the wall and below the junction of the two filters can be found. This kind of airflow will transfer the pollution below to the upper part and send it down again, which will destroy the state of the "piston flow" mentioned above and cause great harm. For local purification equipment with openings connected with the outside world, such as clean workbench, this kind of air flow will inject the polluted air flow. In design, it is necessary to reduce the invalid area occupied by the filter frame, and try to make the wall of the space as close as possible to the effective overlapping air section of the filter.

Through the above analysis, it can be concluded that there are two important preconditions to ensure the characteristics of one-way flow clean room (high cleanliness and rapid self-purification recovery capacity):

(1) Cleanliness of incoming flow

(2) Piston flow of incoming flow

For the cleanliness of the incoming flow, it is not a problem for the one-way flow clean room to supply air through high efficiency filters, but for the "piston flow" of the incoming flow, further analysis is needed. According to the principle of fluid mechanics, the inflow conditions will have a direct and important impact on the flow situation in the future. The outlet air flow of the air supply surface is also the inflow of the working area.

The turbulence of the incoming flow will affect the one-way flow characteristics; if the incoming flow is not filled with the flow cross section, it will affect whether the "piston flow" can be formed behind and how fast it can be formed; and the incoming flow is not filled with the flow cross section is also a factor of the incoming flow. Therefore, under the condition of using high efficiency filter, the necessary condition to ensure the characteristics of one-way flow clean room is "piston flow", while the necessary condition of "piston flow" is that the incoming flow is full of flow cross section. However, for a room rather than a section of pipe, it is unrealistic to fully fill the flow section from beginning to end.

Initially, it was believed that this one-way parallel air flow should fill the whole clean room, but it was technically and economically unfavorable. With the development of knowledge, it is pointed out that this kind of one-way flow only means that all air flows at equal speed along parallel streamlines in a limited field, and that it can restrain the occurrence of eddy currents. A room dominated by the one-way flow characteristics of clean air in full space is also called a one-way flow clean room. That is to say, it is not necessary to have unidirectional parallel streamlines, uniform speed and no eddy current in the whole room, but only to require unidirectional parallel flow characteristics to dominate the room. For example, in the whole working area, this layer of space guarantees unidirectional flow, and this room is a one-way flow clean room. The high cleanliness achieved by one-way flow clean room in the relevant standards and measures at home and abroad introduced above refers to the cleanliness achieved in the working area. Therefore, densely arranged streamlined diffuser top feeding and full orifice plate top feeding are also used as means to realize vertical unidirectional flow.

As a technical enterprise in Shandong Province, which focuses on the design, research, development, construction and installation of hospital operating room purification, dust-free workshop purification, laboratory purification, clean room and other engineering projects, Edward Purification has always been firmly on the road of professional purification engineering construction and development, and it is a trustworthy cleanliness for domestic enterprises. Purification project implementer! For more knowledge of medical purification industry, please pay attention to Wechat Public No. Aide-188 (Ed Purification and Oxygen Supply)