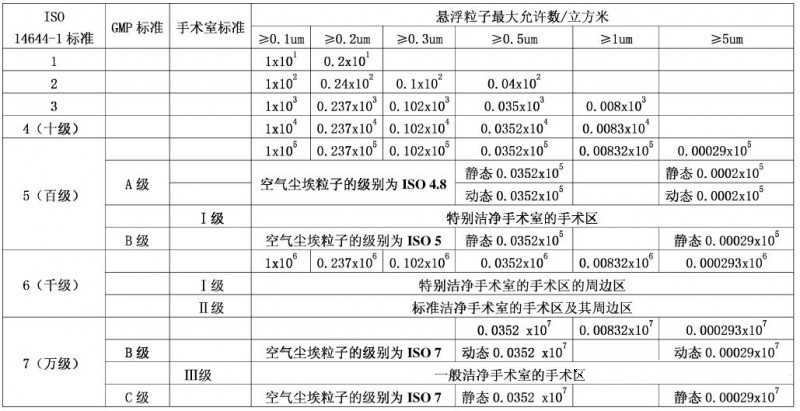

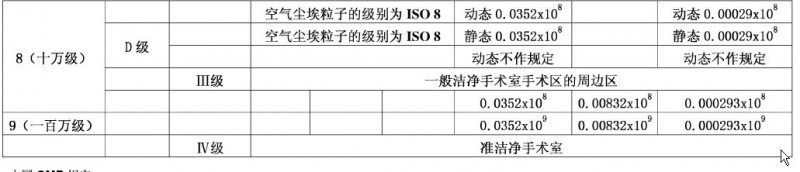

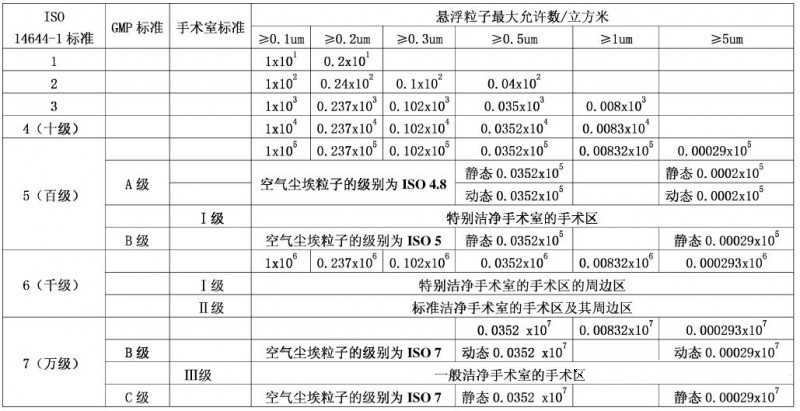

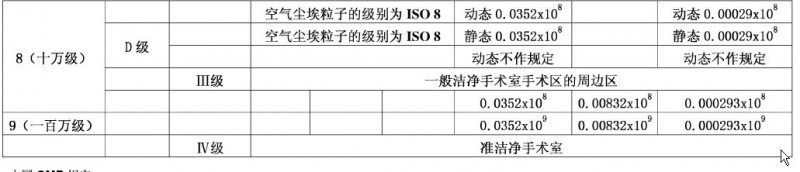

The definition of purification project is to use equipment such as purification air conditioning system to remove dust, bacteria, microorganisms and other pollutants in the air in the space where clean environment is needed, and to stabilize the temperature, humidity, cleanliness, air pressure, air velocity, air gradient, noise, static electricity and other parameters within a certain range according to the requirements of production specifications. Generally, the level of purification engineering can be divided into seven levels: Level 1, level 10, level 100, level 1000, level 10000, level 100000, and level 1000000. The smaller the level of purification engineering is, the higher the level is, the less the dust content is, the higher the level is, and level 1 is the highest. The most common is 100 to 100, 000. As shown in the figure below, the purification engineering grade standard:

Where should each purification level be applied

Level 1: it is mainly used in microelectronics industry, which is the environment with the highest requirements for purification engineering at present. The precision required by integrated circuit shall reach submicron. With the rapid development of microelectronics industry, the requirement of clean room is higher and higher. The example diameter in the timely production room is only 1 μ m, which will also affect the product life. Dust is easy to cause chip failure or stability degradation. When metal dust falls on the integrated circuit, it may cause short circuit. When the acid ions in the air fall on the circuit, it may corrode the circuit, so the purification of air conditioning system is very important for the microelectronics industry. In addition, the production of liquid crystal and optical fiber also needs the requirement of level 1 cleanliness.

Grade 10: mainly used in semiconductor industry with bandwidth less than 2 microns. Its air purification requirements are second only to level 1, and the semiconductor technology in China is also developing, and the requirements for cleanliness will be higher in the future.

Class 100: it is the most commonly used purification project. In addition to the requirements for the number of dust in the air, there are clear requirements for the concentration of bacteria in the air. It is generally used in the pharmaceutical industry for aseptic manufacturing, such as the manufacture of clinical products for implantation into patients, drug production. Medical science experiments are also in this environment, including the breeding environment of experimental animals, genetic engineering experiments, etc. There are also operating room environments such as surgery and transplantation. Isolation environment for bacteria sensitive patients and burn ward are generally among the requirements of 100 level purification project. It can also be used in IC production.

Class 1000: generally only dust concentration is required. It is mainly used for high quality production of optical devices, micro shafts, bearing test and assembly of aircraft gyroscopes, etc.

Class 10000: generally used in the production of hydraulic equipment or pneumatic equipment, and in some cases also used in the production of food and beverage.

100000 level: this level can be used in many purification projects with low requirements, and in many industrial departments, production departments, food and beverage industry, pharmaceutical industry, and parts assembly.

1000000 grade: This grade is the lowest, which means that the number of dust particles with a diameter of 0.5um or more per cubic meter of air is less than 1 million, which can be used in many industries with low requirements for cleanliness. Such as printing factory, packaging factory and so on.

It is self-evident to know the classification standard and application occasions of purification engineering, what kind of purification effect should be achieved in what industry and what grade should be selected!

Shandong ed purification Engineering Co., Ltd. has strong technical strength and construction experience. According to the different needs of clean places, professional equipment is used to form different levels of clean standard space and create the most suitable production and working environment. At present, it has established close cooperation with many enterprises and is a reliable professional purification project implementer. For more knowledge of medical purification industry, please pay attention to WeChat public address: Aide-188 (Ed purify oxygen supply).