As a professional project design, system engineering construction, supporting product sales purification engineering enterprise, Edward Purification has professional secondary qualification of purification engineering, strong strength, rich experience, strict to every detail of purification engineering, to ensure the quality of purification operation room, is a trustworthy purification manufacturer for customers. To learn more about the medical purification industry, please pay attention to the Wechat Public No. Aide-188 (Ed Purification and Oxygen Supply)

The construction process of integrated hybrid operating room is comprehensive and complex. Hospital needs to organize clinical departments (using departments), general infrastructure services (selecting site environment), medical engineering (equipment selection and installation), Information Department (information technology integration), imaging department (image technology operation) and equipment manufacturers, purification professional companies and general design companies. Due to the difficulty of system maintenance and quality and safety technical support, it is necessary to conduct comprehensive testing and technical acceptance, operation and maintenance training before delivery, in order to really play its role and achieve the desired purpose.

1. Key Points of Construction of DSA Composite Operating Room

DSA, a digital subtraction angiography system suitable for multi-equipment and multi-team cooperation, can collect, store and process various angiographic images in real time.

DSA complex operating room can carry out the following types of operations: cardiothoracic surgery, vascular surgery, neurosurgery, hepatobiliary surgery. Avoid the risk of transportation between operating room and catheter room, and reduce the degree of injury.

01 Site Requirements

There are many equipments in the compound operating room. It is necessary to ensure enough space for layout and operation, and to meet the laminar flow standard for operation. Clean operating rooms, operating rooms and equipment rooms are generally required. The operating room space is more than 80_, considering the equipment trajectory. The net height of the operating room is 2.9-3.0m, and the floor height is controlled from 4.5 to 4.8m. Considering the need for embedded steel frame to support the sweeping bed, laying electric wire trough and radiation protection, the design of regional floor subsidence structure is considered, and 250-300mm is controlled.

Surgical equipment: cardiopulmonary bypass system, thoracoscopic and laparoscopic system, real-time cardiac ultrasound system, anesthesia machine, monitoring system, electrophysiological equipment, electrosurgical knife workstation, high-resolution monitor, high-pressure syringe, operating lamp, lead coat or screen, all kinds of suspension tower and multi-functional operating bed.

02 Video Acquisition and Transmission System and Information Integrated Management System

Integrate equipment and systems with different brand specifications. Central station control; access to storage information with HIS, RIS, LIS, RACS and other systems; establish a connection with hospital information network; remote medical consultation, teaching video system.

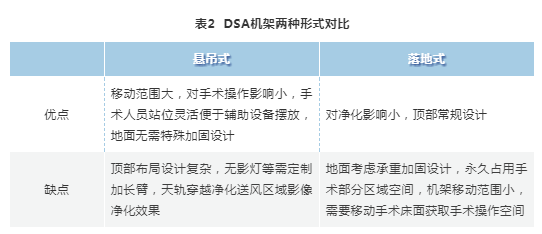

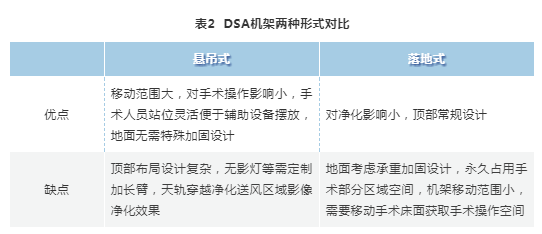

DSA requires high technical indexes such as the structure, arm length, rotation angle and moving distance of C-arm machine. It can be selected according to the equipment description. There are two types of rack at present. Hospitals need to consider the imaging quality of the equipment, the type of operation and the site conditions to select the appropriate rack.

03 Clean Technology and Key Points of Coordination

The purification level of cardiovascular surgery should be level III, and the purification level of cardiac surgery should be level I. The installation mode of vascular machine should be fully considered to avoid setting steel frame in purification air supply area of operation center. Because of the high calorific value of water cooler and power supply cabinet, the refrigeration requirement should be considered; the requirement of rapid heating and cooling should be considered in accordance with the environmental requirement of different operation stages; the medical gas interface should be reserved, besides conventional oxygen, compressed air, vacuum suction, laughing gas and anesthetic exhaust gas, argon knife, cardiopulmonary bypass machine and other gases which need argon, carbon dioxide and nitrogen. Interface.

2. Key Points of Construction of MRI Compound Operating Room

MRI compound operating room is mostly used in neurosurgery. It uses intraoperative localization and evaluation of the operation effect. It combines localization technology, nerve intervention and surgery, such as transcatheter resection of abnormal blood vessels.

Generally, there are movable screen doors in operating room, operating room, magnet equipment room, operating room and magnet equipment room.

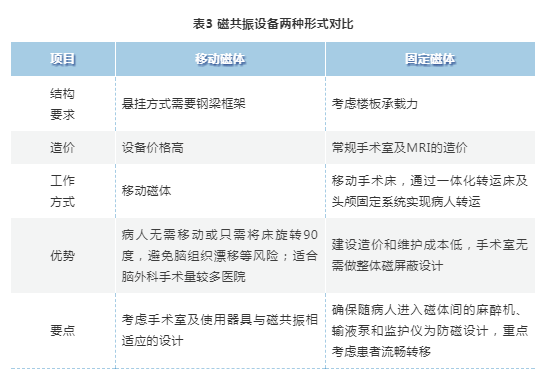

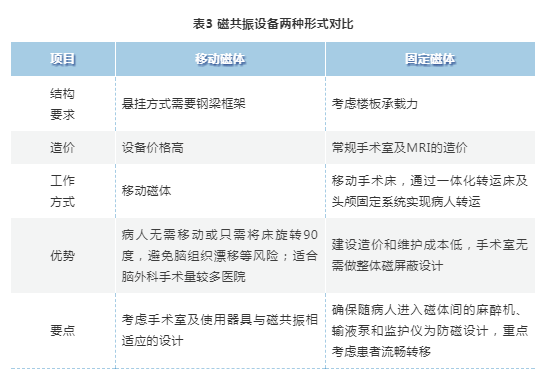

There are two kinds of magnetic resonance equipment: fixed magnet and mobile magnet. It is necessary to select the type as soon as possible to avoid the high cost of reinforcement (Table 3).

First of all, we need to pay attention to site selection, magnet transport path, environmental impact, equipment selection, pipeline impact and other factors as the general construction of MRI. Combining with the regional design of the operation department, the preparation of the pre-stage site should be very careful, including space, load-bearing, electrical, vibration, humidity, altitude, electromagnetic interference, air quality and lighting conditions, as well as the requirements of quench tube placement, radio frequency shielding and launching.

01 Architectural Design

Floor height is 4.2-4.8m. No vibration equipment should be installed in the upper area. The horizontal distance between the MRI compound operating room and the elevator is not less than 10m.

02 electromechanical design

It not only realizes the maintenance of electromagnetic shielding, but also meets the standard requirements of clean operating room. The shielding and filtering of purified air duct, medical gas pipeline and electrical pipeline need to be solved.

03 Decoration Design

Decoration materials such as partition walls and keels for smallpox need non-magnetic non-metallic materials. The ground can distinguish the Gauss line by different color according to the intensity of magnetic field, which is helpful for medical staff to remove the non-magnetic compatible medical equipment from the 50 Gauss line during magnet scanning.

04 Lighting Design

The room lighting requirements for general surgery, endoscopic surgery and magnet scanning are considered comprehensively.

05 Purification Air Conditioning Design

Mobile magnet condition: There is no need to purify itself in the nuclear magnetic examination room, but there is a large pressure difference in opening the mobile shield door, which will cause unstable air flow and affect the clean room environment. In order to control the cleanliness and airflow organization of the operating room and maintain a certain pressure difference, it is necessary to consider the purification between the nuclear magnetic equipment. If the operating room outside the brain needs to have the cleanliness level I, and the same cleanliness level I is set in the nuclear magnetic examination room, the standard is too high and energy-saving. In some cases, the nuclear magnetic examination room is designed as a variable air volume system. When the shielding door is closed, the two rooms are relatively independent and the nuclear magnetic examination is carried out. According to Class III clean room standard, before the shield door is opened, the cleanliness level of the nuclear magnetic examination room is raised to Class II clean operating room standard. After the shield door is opened and connected, the clean environment of the operating room is less affected and energy-saving.

06 Fixed magnet condition

The cleanliness should be set according to the need of operation.

As a professional project design, system engineering construction, supporting product sales purification engineering enterprise, Edward Purification has professional secondary qualification of purification engineering, strong strength, rich experience, strict to every detail of purification engineering, to ensure the quality of purification operation room, is a trustworthy purification manufacturer for customers. To learn more about the medical purification industry, please pay attention to the Wechat Public No. Aide-188 (Ed Purification and Oxygen Supply)